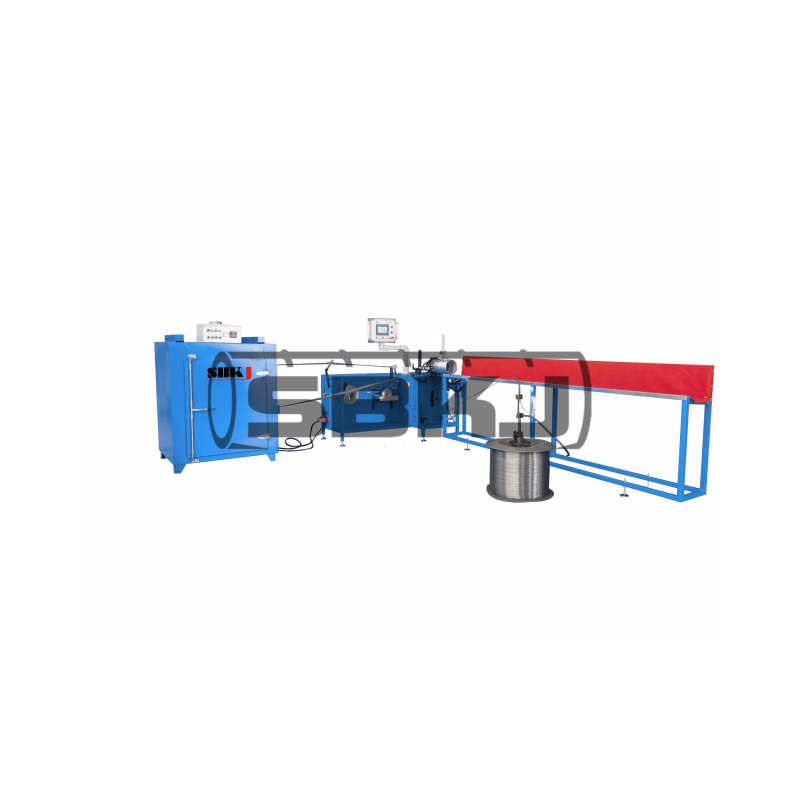

SBRL-200A is more suitable for exhaust fumes, as well as tropical and subtropical regions. This device includes a host, a drying oven, and a material rack.

SBLR-200A uses water-based adhesive. This type of adhesive does not contain organic solvents and heavy metals, making it more environmentally friendly. Its heat resistance is also stronger than that of solid hot melt adhesive, so it can be used for removing oil fumes. SBLR-200A uses aqueous hot melt adhesive. This type of adhesive does not contain organic solvents and heavy metals, making it more environmentally friendly. Its heat resistance is also stronger than that of solid hot melt adhesive, so it can be used for removing oil fumes. However, aqueous hot melt adhesive have a slow bonding speed and lower viscosity at low temperatures. In addition, the device can also add an extra layer of PVC to achieve a three-layer sturdy pipeline consisting of two layers of aluminum foil, one layer of PVC, and one steel wire.

| Technical Data | |

| Diameter | 80-600mm |

| Material | Aluminum foil |

| Thickness | 0.02-0.08mm |

| Width | 30-50mm |

| Feeding Speed | 80m/min |

| Cutting System | Automatic cut |

| Power | Mainframe 1.5kW,Drying oven 7.5kW |

| Voltage | 380V/50HZ/3PH |

| Dimension | Drying oven:1150×1050×1680mm |

| Mainframe:1860×950×1000mm | |

| Run-out table:2200×800×1250mm | |

| Weight | 980Kg |