The Village Blacksmith: Are you a welder? Do you know what a seam welder is? A seam welder is specifically designed to create repetitive welds that are strong and durable. This device is quite beneficial to metalworkers who be compelled to securely and adequately attach materials.

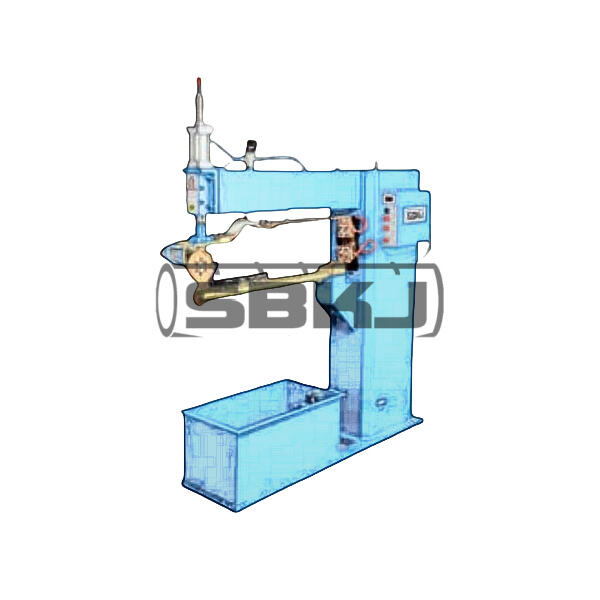

A seam welder is an industrial machine, which is designed to weld two metal plates with each other along a seam. It has a spinning wheel that presses down on the metal while it is being heated with electricity. When the metal is heated it softens and will stick together. This generates a robust weld which firmly joins the steel parts. In factories and workshops, seam welders are used to fabricate critical components, such as oil and gas piping and storage tanks. These do have to be sealed extremely tightly to avoid leaking, and seam welders are perfect for the job.

A seam welder can therefore be of great time saving and energy saving upper hand to you if you are working on a large welding project. Perfect for big projects, this machine3 effectively welds long pieces of metal together with ease. Compared to other welding processes, such as spot welding, where many tiny welds have to be made, seam welding is a continuous process that can supply the whole length of the weld without breaking. This means you don’t need to stop what you’re doing or drag the metal around. Unlike a regular welder, you can just run your seam welder down the metal length, speeding up and simplifying your project.

Watertight Seal — Since seam welders create a continuous weld, they can form seals that won't let water seep through. You will need this compound for projects where liquids need to be safely contained inside without leaking out, as for example pipes or storage tanks.

Efficient: Seam welding is much faster than other welding processes, because you can weld continuously. Which does save you both time and money on your welding projects. You can get your jobs done more quickly and you can spend less on materials.

Robust and Resilient Welding: Seam welding creates a continuous fused joint that is more robust and resilient than any other form of welding. When also adding more durable and resistant material we mean longer-lasting and with less maintenance when time passes.

More Efficient: Seam welding is carried out in a continuous and smooth manner. It means you can work with greater efficiency than with any other welding method, which may necessitate frequent stops and starts. With this efficiency, it can significantly accelerate your project.

SBKJ Group has its headquarters in the Yangtze River Delta near Shanghai, China. SBKJ is a manufacturer of spiral tubeformer with over 30 years experience. SBKJ spiral tubes can be made to meet SEAM WELDER, BS Euroorm and Smacna standards. More than 60 nations are represented by our clients.

We offer a dedicated customer service rep for each customer and an SEAM WELDER with a fixed number and an after-sales WeChat Group dedicated to the after-sales. Online, you can locate us easily. We'll be able to resolve your problems using the Internet. SBKJ equipment is guaranteed by a life-time maintenance plan and a warranty for one year.

SBKJ is recognized as the most renowned and leading manufacturer of spiral ducts using patented inventions such as the Flying silitter and SEAM WELDER. SBKJ's research and innovation is the foundation of our automated tubeformers, which produce top quality pipes with reduced costs of production.

SBKJ offers OEM services. You can choose to remove the SBKJ logo from your device or request a custom device color. You can choose the language of the program, provided you have translated SEAM WELDER. We can also customize your equipment according to the needs of your production