Spot welding machines are extremely useful equipment that helps weld two metals. They use electricity to fuse sheets of metal together, a more efficient and accurate process compared to previous welding systems. This means that using a spot welding machine allows the metal pieces to fit closely together and provide more strength with how they are joined.

Metal work deals with various functionalities such as cutting, bending and shaping metal. However, using spot welding machines completes this task way faster and easier. This means they make the process of "welding" metal parts together quicker and saves time. Since less welding is necessary, everything is completed faster with these machines. There are many factories and workshops that have these machines because they can save time as well as money, enabling them to make more items in lesser time.

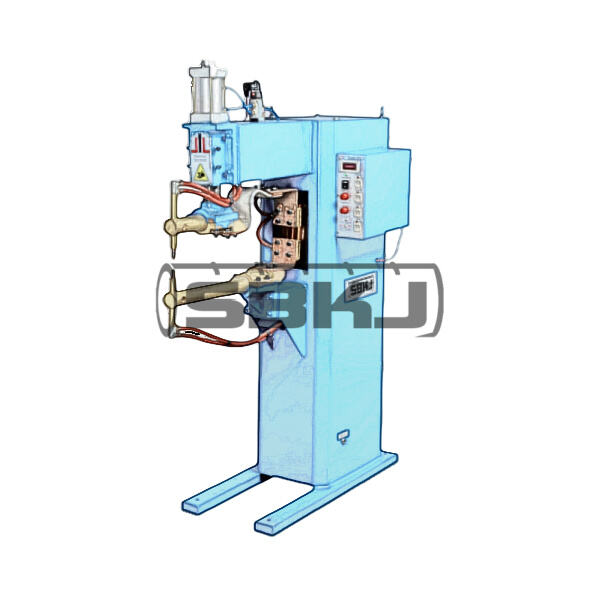

Spot welding machines are widely used for cars and different types of industries. These machines are responsible for welding the metal parts that constitute a car's body and frame. It's highly vital, as we require tough and secure vehicles. Because spot welding machines are suitably precise the way to join diverse automobile components with asphalt deficiencies. In the auto industry, one of the most common types is called SBKJ SPIRAL TUBEFORMER. It is favored because this machine delivers quality and performance required by car manufacturers at an economic cost.

There is a whole bunch of reasons as to why you should make use of spot welding machines. One, these machines help avoid errors in production. This means that the end products are better, more accurate, and higher quality. Second, the spot welding machines can weld even the thinnest sheets of metal, which is great for designing lightweight structure. Third, they reduce costs of production, meaning it is cheaper for the firm to produce their products. Finally, these machines can work on different metals and provide reliable results each time with regards to quality consistency during production.

Spot welding machines are one of the vital equipment in any manufacturing industry today. Which enables factories to have automation at work, and thus, factories are now able to produce items with significantly more speed. And this has enabled several industries move to deliver the product for what it is expected timely. The SBKJ SPIRAL TUBEFORMER is at the forefront of these developments. It makes constant revisions on its spellings to serve the requirements of its clients more perfectly.