In any field related to HVAC and ventilation, the need for ducting options tailored to quality, durability, and flexibility increases. Most notable of factors contributing to this trend is the increase which is the Aluminum Flexible Duct Forming Machine, a state of the art equipment developed for making very effective and multifunctional aluminum foil ducts. This article examines more about the aluminum foil flexible ducts – their purpose, properties, and benefits, bonding methods, the newest updates on the equipment, and how to cut them.

The Function of Aluminum Foil Flexible Duct

The use of Aluminum foil flexible ducts has become popular in heating, ventilation, and air conditioning systems because they are light in weight, can be folded and installed with ease. Such ducts are important as they allow the other rooms or parts of the building to be ventilated by air from the main HVAC unit. Especially in tight or awkward spaces, being able to make bends and curves where standard metal duct-work cannot is useful. In addition, aluminum foil ducts provide good thermal insulation so that the temperature of the moving air is optimal and energy is not wasted.

Properties and Benefits of Aluminum Foil Flexible Duct

The case of aluminum foil flexible ducts is that they have unique properties that supersede those of the conventional ducting method. To begin with, they resist corrosion, moisture, and fire and so their safety and the durability are enhanced. For another, this type of duct is made of aluminum foil, which is rather thin but very pliable and therefore, it can bend in many directions and even in confined areas. Thirdly, their ducts tend to be lightweight, for this reason, they are easily transported and installed.

In addition, the benefits of aluminum foil flexible ducts do not only lie in their physical characteristics. They also help save on costs in their operations as these do not consume a lot of energy and they are not much of complicated maintenance. The reflective covering also acts in a way that heat is not absorbed thereby aiding in the effective dispersion of air. Moreover, it is not complicated to install since one does not require expertise or any special equipment, hence, it is quick and simple in use for professionals and amateurs alike.

Bonding Aluminum Foil – 2 Types of Glue Used in Aluminum Foil Bonding—Solids and Liquids

Bonding of aluminum foil flexible ducts forms an integral process in the production of such ducts, and the adhesive used influences the functioning of such ducts. There are two main types of glue which are used for the above purpose: Bongers that expand (solids) and spray anxodist (liquids).

Popular hot-melt adhesives belong to the category of solid glue having the advantages of faster curing and versatile bonding strength. Their mechanism describes melting the adhesive to its liquid state prior to applying it to the surfaces to be adhered together. It has the mastic that once cooled, hardens, and forms strong and protective material.

Solvent and water based adhesives are categorized as glues. Such types of adhesives do not usually dry quickly and are less useful because of the time frame required. These standard speeds are ideal for polyurethane glue due to the fact that the duct system is subjected to tension significantly and could be used in a lot of activity that tends to fatigues up duct hoses.

New Item Update: wrapped in a PVC material - PVC aluminum foil composite hose.

There is a newer innovation in aluminum foil flexible duct technology whereby a PVC (Polyvinyl chloride) material was added to the lantern making it a PVC aluminum foil composite hose. Such a composite construction allows the creation of ducting that adds the benefits of both materials to standard shaped PVC foil ducting. PVC is not only flexible but is also highly durable and has a number of protection features such as resistance to ultraviolet light and various chemicals. Aluminum foil is ducted externally with PVC in a composite hose so its application is extended as well.

These composite hoses are very much suited for the applications where a good amount of flexibility and durability repossess high importance. Hence, they can be used advantageously in tougher kinds of HVAC installation. Besides, the additional covering of PVC also helps in improving the wear resistance of the duct thus, increasing its lifespan.

Common Cutting Methods for Aluminum Foil Hoses Using Specialized Scissors

After the aluminum foil is constructed, further alterations are necessary to install it. A common and effective way of cutting aluminum foil hoses has been sited to be a manual method using scissors. Such scissors are tailored to cut aluminum foil without distorting the edge profile of the tube walls. Manual cutting gives more precision and is most applicable during adjustment of limited quantities or at the site and is thus useful for HVAC practitioners.

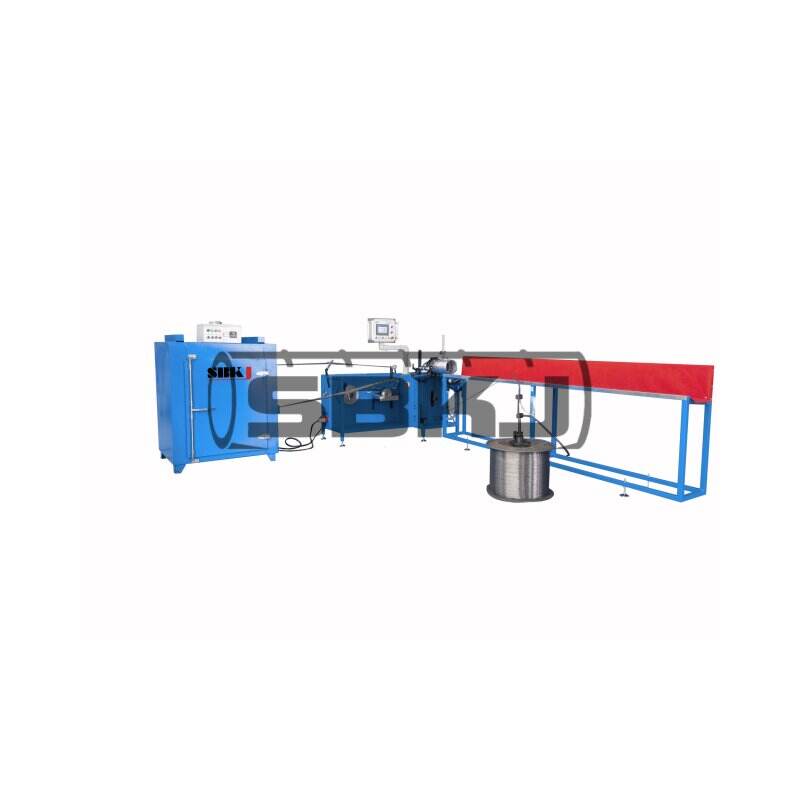

SBKJ Equipment High-Speed Automatic Cutting

For those operating at larger capacities where both efficiency and accuracy are put to the test, SBKJ equipment includes high-speed automated cutting systems. These heavy duty machines are designed to cut aluminum foil ducts at a very high speed and/ or a very high degree. With automated cutting, there is large reductions in skill and equipment costs and also improved quality of the cuts on every duct to minimum standards. With the employment of such high-speed automatic cutting equipment, it can be said that there is an advancement in the manufacturing process necessary to meet the high requirements of present-day heating, ventilation, and air conditioning HVAC systems.

Conclusion

An icing duct forming machine stands out in the hierarchy of tools in the air handling and ventilation system due to the milestones achieved in the revolution of HVAC. In the line of its main purpose and a number of advantages, this machine has also changes and improves because of new materials and cutting technologies. Whether through manual chord scissors or SBKJ equipment, as far as leading, designing, and manufacturing these ducts is concerned, there will always be production and scope for communities to change over time. With new developments coming in, one is certain that the aluminum flexible duct forming machine will still hold its position as one of the most important tools in the hands of HVAC specialists.

Table of Contents

- The Function of Aluminum Foil Flexible Duct

- Properties and Benefits of Aluminum Foil Flexible Duct

- Bonding Aluminum Foil – 2 Types of Glue Used in Aluminum Foil Bonding—Solids and Liquids

- New Item Update: wrapped in a PVC material - PVC aluminum foil composite hose.

- Common Cutting Methods for Aluminum Foil Hoses Using Specialized Scissors

- SBKJ Equipment High-Speed Automatic Cutting

- Conclusion

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

HY

HY

BN

BN

LO

LO

LA

LA

MN

MN

NE

NE

UZ

UZ

KY

KY