Vesnický kovář: Jste svářeč? Víte, co je švová svářečka? Svářečka je speciálně navržena pro vytváření opakujících se svarů, které jsou pevné a odolné. Toto zařízení je velmi výhodné pro kovodělníky, kteří jsou nuceni bezpečně a adekvátně připevňovat materiály.

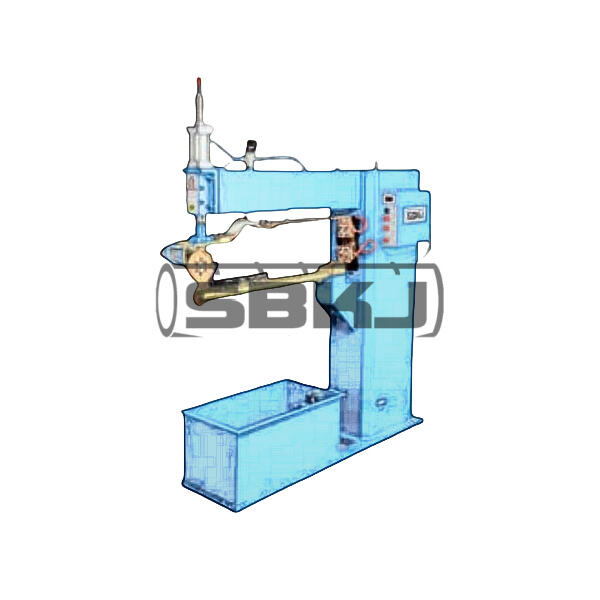

Svářečka je průmyslový stroj, který je navržen tak, aby svařoval dvě kovové desky navzájem podél švu. Má rotující kolo, které tlačí na kov, zatímco se zahřívá elektřinou. Když se kov zahřeje, změkne a bude se lepit. To vytváří robustní svar, který pevně spojí ocelové díly. V továrnách a dílnách se švové svářečky používají k výrobě kritických součástí, jako jsou potrubí na ropu a plyn a skladovací nádrže. Ty musí být extrémně těsně utěsněny, aby se zabránilo úniku, a švové svářečky jsou pro tuto práci ideální.

Pokud pracujete na velkém svářečském projektu, může vám švová svářečka výrazně ušetřit čas a energii. Tento stroj3 je ideální pro velké projekty a snadno svařuje dlouhé kusy kovu. Ve srovnání s jinými svařovacími procesy, jako je bodové svařování, kde je třeba provést mnoho drobných svarů, je švové svařování kontinuální proces, který může dodat celou délku svaru bez porušení. To znamená, že nemusíte zastavovat to, co děláte, ani tahat kov kolem. Na rozdíl od běžné svářečky můžete švovou svářečku spustit po délce kovu, čímž urychlíte a zjednodušíte svůj projekt.

Vodotěsné těsnění — Vzhledem k tomu, že švové svářečky vytvářejí souvislý svar, mohou vytvořit těsnění, které nepropustí vodu. Tuto směs budete potřebovat pro projekty, kde musí být kapaliny bezpečně uloženy uvnitř, aniž by unikaly, jako jsou například potrubí nebo skladovací nádrže.

Efektivní: švové svařování je mnohem rychlejší než jiné svařovací procesy, protože můžete svařovat nepřetržitě. Což vám ušetří čas i peníze na vašich svařovacích projektech. Svou práci zvládnete rychleji a utratíte méně za materiály.

Robustní a odolné svařování: Švové svařování vytváří spojitý tavený spoj, který je robustnější a odolnější než jakákoli jiná forma svařování. Když přidáme také odolnější a odolnější materiál, máme na mysli delší životnost a méně údržby, když čas plyne.

Efektivnější: švové svařování se provádí kontinuálním a hladkým způsobem. To znamená, že můžete pracovat efektivněji než s jakýmkoli jiným způsobem svařování, což může vyžadovat časté zastavování a spouštění. Díky této efektivitě může výrazně urychlit váš projekt.

SBKJ Group má své sídlo v deltě řeky Yangtze poblíž Šanghaje v Číně. SBKJ je výrobcem spirálových tvarovačů trubek s více než 30 lety zkušeností. Spirálové trubky SBKJ lze vyrobit tak, aby splňovaly normy SEAM WELDER, BS Euroorm a Smacna. Našimi klienty je zastoupeno více než 60 zemí.

Nabízíme vyhrazeného zástupce zákaznických služeb pro každého zákazníka a svářeče švů s pevným číslem a poprodejní skupinu WeChat, která se věnuje poprodeji. Online nás můžete snadno najít. Budeme schopni vyřešit vaše problémy pomocí internetu. Na zařízení SBKJ se vztahuje doživotní plán údržby a záruka na jeden rok.

SBKJ je uznáván jako nejrenomovanější a přední výrobce spirálových potrubí využívajících patentované vynálezy, jako je Flying silitter a SEAM WELDER. Výzkum a inovace SBKJ jsou základem našich automatizovaných tvarovačů trubek, které produkují trubky nejvyšší kvality se sníženými výrobními náklady.

SBKJ nabízí OEM služby. Můžete se rozhodnout odstranit logo SBKJ ze zařízení nebo požádat o vlastní barvu zařízení. Můžete si vybrat jazyk programu, pokud jste přeložili SEAM WELDER. Můžeme také upravit vaše zařízení podle potřeb vaší výroby