Numquam fueris perplexis videns metalla tubus coniuncta et congruenter absque aliquibus asperis aut inaequalibus lateribus? Hoc vocatur sutura! Sutura est processus importantis qui adiuvat coniungere duas partes metalli ita ut videantur et sentiantur quasi unum continuum opus. Est veluti componere bene aptum puzzle sine ulla interstitia inter partes.

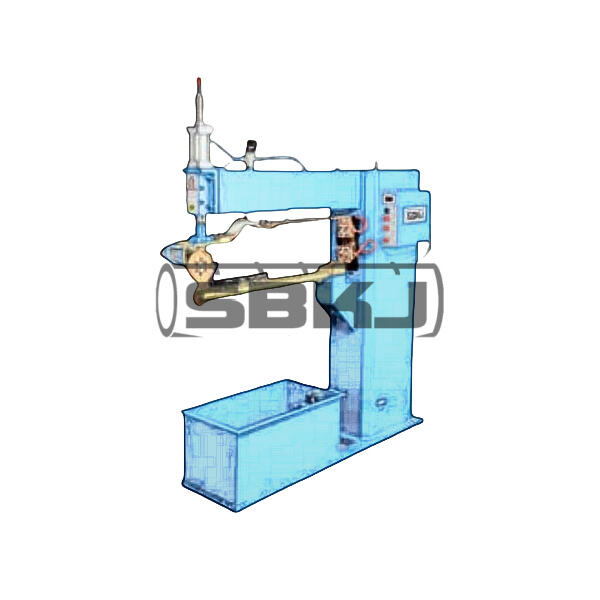

Sutura requirit specialia instrumenta quod appellatur suturae faber. SBKJ SPIRAL TUBEFORMER est una ex societatibus quae conficiunt haec machina. Eorum machinae sunt valde elaboratae, utentes arte recentissima ad diligenter coordinandum fragmenta metalli et coniungendum ea simul. Suturae sunt firmae et pulchrae, resultantes in meliore producto!

Non inventae erant machinae suturarum donec postea, itaque homines manu metalia soderent. Hoc erat processus tardus et difficilis ad implementum, sed multam tempus et curam requirebat. Erat etiam minus sophistica, quod significabat interdum eas solduras non esse tam fortes quam opus erat. Uti apparatus SBKJ SPIRAL TUBEFORMER facit processum soldurandi multo celeriorem et faciliorem. Non solum hoc tempus et pecuniam servat pro pluribus negociis, sed etiam est elementum cruciale in omnibus negotiis felicibus.

Tecnologia intellegens utilisatur in machinis pro sutura marginis ut certum fiat partes metallicas perfecte coniungantur. Hae machinae calefaciunt partes metallicas — valde, valde calidas — cum laser. Postea torqueuntur ut pressio coniugat metallum postquam est calefactum. Hoc format vinculum perpetuum et difficile frangendum inter duo metalla. Hoc est importante rebus quae debent esse fortes et fideles.

Machinae SBKJ SPIRAL TUBEFORMER sunt bene notae propter maximam versatilitatem. Potentes sunt formare varietatem generum metallorum, inter quae alumenium, ferrum, et multa alia. Quod significat eas applicabiles ad multas industrias, sive sit fabricatio automobilium, aedificatio structurarum aut productio rerum domesticarum. Et sive quid sit pars metallica quae coniungi debet, haec machina omnia potest!

Machina ad suturas soldandas invenit multas applicationes in variis industriis per orbem. Notabiliter utuntur earum in industria automotiva ubi componentia critica, sicut muta et tubuli exhausti, fiunt ex hoc gradu machinabili. Haec partes sunt crucialia pro recto operatione automotorum. Item utuntur in industria constructionis ad creanda frames metallicae aedificiorum. Fortes frames metallicae sunt crucialia ad certificandum aedificia secura et fortem esse.

SBKJ SPIRAL TUBEFORMER conficit machinas adaptabiles ad quamvis industriam. Possunt machinas conficere accommodatas necessitatibus societatis. Facit productionem efficientius et amicabilius budget habendo machinas quae congruunt cum necessitatibus societatis. Hoc est utile negotiis quia parvam pecuniam consumunt et possunt vendere sua mercimonia suis clientibus ad meliores pretia.

Habemus devotum clientium servitium SEAM WELD FABRICANDI MACCHINA cuiusque clienti praeter certam Post-Venditionem Servitium Lineam calidae et post-venditionem WeChat Group devotum ad post-venditionem. Facilis accessus sumus in rete. Per internettum quoque confidendo, possumus te prompte adiuvare et tibi in solvendo problematis adiuvare. SBKJ instrumenta sub annuo warrantio et vitam aeternam cum mercede manutenentur.

SBKJ multos annos praecursor fuit in fabrica ductorum spiralium. Plura patentia habent, inter quae Flying silitter, Flying crinnper et Flying teeter. Designatio et investigatio SBKJ fundamentum est machinarum nostrarum SEAM WELD MAKING MACHINE, quae sunt automatae et producunt ductus altissimae qualitatis cum minoribus dispendiis.

Civitas SBKJ sita est in Delta Fluminis Yangtze in China, iuxta Shanghai. SBKJ habet peritiam maiorem quam SEAM WELD MAKING MACHINE in fabricando tubum spiralem ex anno 1995. SBKJ certificatur ISO9001: 2000 et CE. Tubi spirales SBKJ possunt fieri ad normas DIN, BS Euroorm et Smacna. Clientes nostri repraesentant plus quam 60 nationes.

SBKJ praebet servitium OEM. Potes eligere ut amoves logom SBKJ a machina aut requiras colorem machinae customizatum. Potes eligere linguam programmatum, dummodo minores linguas ipse transtuleris. Potes etiam machinam customizare ut aptetur tuae necessitatibus SEAM WELD MAKING MACHINE.