Boli ste niekedy zmätení, keď ste videli, ako sa kovové rúry spájajú a dokonale do seba zapadajú bez akýchkoľvek nerovností alebo drsných hrán? Tomu sa hovorí švové zváranie! Švové zváranie je rozhodujúci proces, ktorý pomáha pri spájaní dvoch častí kovu tak, že vyzerajú a pôsobia ako jeden hladký kus. Je to ako poskladať dobre uchytenú skladačku bez medzier medzi dielikmi.

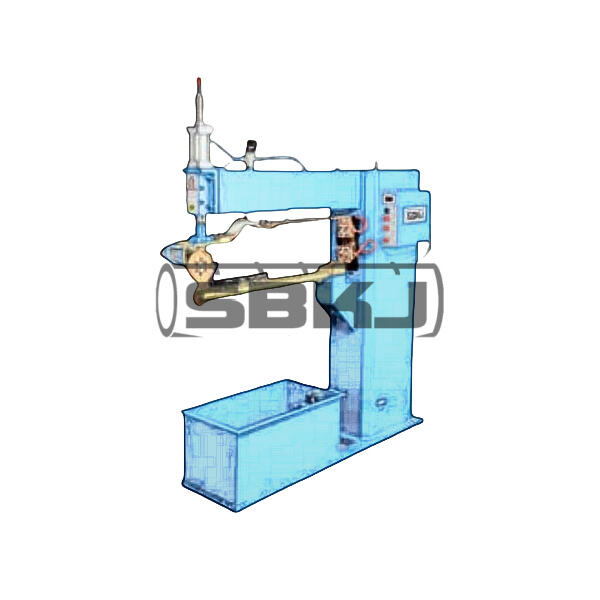

Zváranie švov vyžaduje špeciálne zariadenie známe ako zváračka švov. SBKJ SPIRAL TUBEFORMER je jednou zo spoločností, ktorá vyrába tieto stroje. Ich stroje sú vysoko sofistikované a využívajú najmodernejšie technológie na jemné zarovnanie kovových kusov a ich spojenie. Zvary sú pevné a pekné, výsledkom čoho je krajší konečný produkt!

Stroje na švové zváranie boli vynájdené až neskôr, takže ľudia zvárali kovy ručne. Tento proces bol pomalý a náročný na implementáciu, ale vyžadoval si veľa času a starostlivosti. Bolo to tiež menej sofistikované, čo znamenalo, že niekedy tieto zvary neboli také silné, ako by potrebovali. Použitie zariadení SBKJ SPIRAL TUBEFORMER výrazne urýchľuje a uľahčuje proces zvárania. To nielen šetrí čas a peniaze pre väčšinu podnikov, ale je to kľúčový prvok vo všetkých úspešných podnikoch.

Na strojoch na švové zváranie sa používa inteligentná technológia, ktorá zabezpečuje dokonalé spojenie kovových častí. Tieto stroje zahrievajú kovové časti - veľmi, veľmi horúce - laserom. Nakoniec sú skrútené tak, že tlakové zváranie kovu po jeho zahriatí. To vytvára trvalé a ťažko prerušiteľné spojenie medzi týmito dvoma kovmi. To je dôležité pre veci, ktoré musia byť tvrdé a spoľahlivé.

Stroje SBKJ SPIRAL TUBEFORMER sú dobre známe tým, že sú veľmi univerzálne. Sú schopné kovať s rôznymi druhmi kovov, vrátane hliníka, ocele a mnohých ďalších. To znamená, že sú použiteľné v mnohých rôznych odvetviach, či už ide o výrobu automobilov, stavbu budov alebo výrobu domácich potrieb. A bez ohľadu na to, akú kovovú časť je potrebné zložiť, tieto stroje to všetko zvládnu!

Stroje na švové zváranie nachádzajú mnoho aplikácií v rôznych priemyselných odvetviach po celom svete. Používajú sa najmä v automobilovom priemysle, kde sa kritické komponenty, ako sú tlmiče výfuku, výfukové potrubie, vyrábajú z tejto opracovateľnej triedy. Tieto diely sú kľúčové pre správne fungovanie auta. Používajú sa aj v stavebníctve na vytváranie kovových konštrukcií budov. Silné kovové rámy sú rozhodujúce pre zaistenie bezpečnosti a pevnosti budov.

SBKJ SPIRAL TUBEFORMER vyrába stroje prispôsobiteľné každému odvetviu. Sú schopní postaviť stroje prispôsobené potrebám spoločnosti. Vďaka tomu je výroba efektívnejšia a cenovo výhodnejšia vďaka strojom, ktoré sú v súlade s potrebami spoločnosti. To je dobré pre podniky, pretože ušetria peniaze a svoj tovar môžu predávať svojim zákazníkom za výhodnejšie ceny.

Okrem pevnej linky popredajného servisu a popredajnej skupiny WeChat, ktorá sa venuje popredajnému servisu, máme pre každého zákazníka špecializovaný zákaznícky servis. Sme ľahko dostupní na internete. Spoliehaním sa aj na internet vám vieme promptne pomôcť a pomôcť pri riešení problémov. Na zariadenia SBKJ sa vzťahuje 1-ročná záruka a doživotná platená údržba.

SBKJ je už mnoho rokov priekopníkom vo výrobe špirálových potrubí. Majú niekoľko patentov vrátane Flying silitter, Flying crinnper a Flying teeter. Dizajn a výskum SBKJ je základom pre náš STROJ NA VÝROBU ŠVOVÝCH ZVAROV, ktorý je automatizovaný a ktorý vyrába vysokokvalitné potrubia s nižšími nákladmi.

SBKJ Group sídli v delte rieky Yangtze v Číne neďaleko Šanghaja. SBKJ má viac ako STROJ NA VÝROBU ŠVOVÝCH ZVAROV od roku 1995 s odbornosťou na výrobu špirálových tvarovačov rúrok. SBKJ je certifikovaný podľa ISO9001: 2000 a CE. Špirálové rúrky SBKJ je možné vyrobiť podľa noriem DIN, BS Euroorm a Smacna. Našimi klientmi je zastúpených viac ako 60 krajín.

SBKJ ponúka služby OEM. Môžete sa rozhodnúť odstrániť logo SBKJ zo zariadenia alebo požiadať o prispôsobenú farbu zariadenia. Môžete si vybrať, v ktorom jazyku je program, pokiaľ ste prekladali vedľajšie jazyky. Môžete si tiež prispôsobiť vybavenie tak, aby vyhovovalo vášmu STROJU NA VÝROBU ŠVOVÝCH ZVAROV.