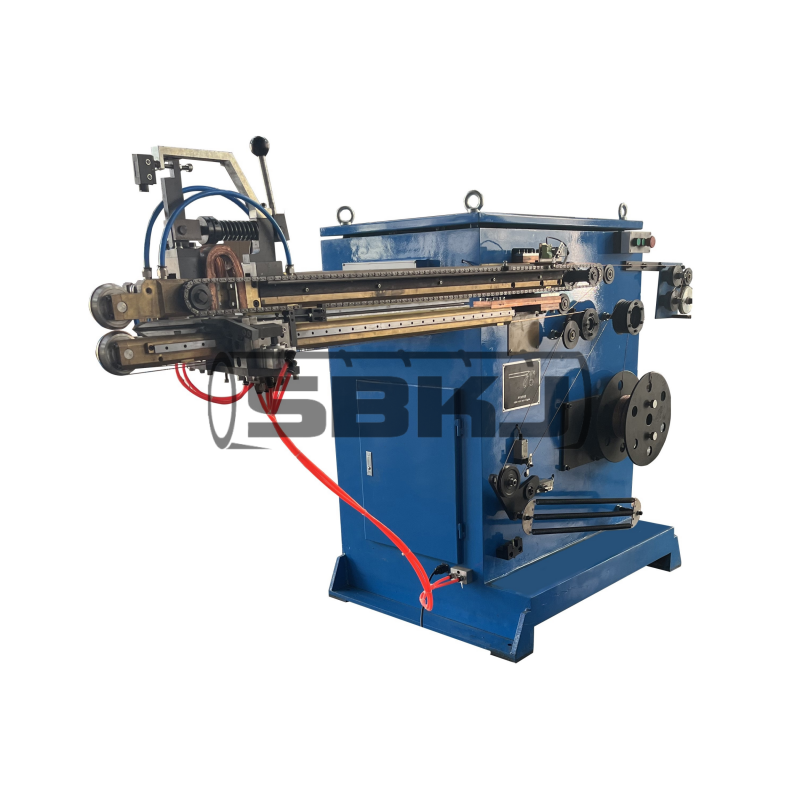

SBSW-30-2Z is a new type of welding machine designed by our company for the can making and ventilation pipeline industry. Due to the use of advanced microcomputer control technology, its performance is more stable and operation is simpler.

By improving the structural form of traditional semiautomatic welding

machine,SBSW-30-2Z can increase the rate of transporting cans and keep the higher production.Theequipment adopts the double wires technology, preventing the pollution of middle electrodes effectively, securing the quality of welding line and the beautiful appearance.Using Mitsubishi programmable controller as its controlling centre andDelta converterto adjust the main drive speed, all electronic components and devices being burn-in screened, the machine has a long life and stable capability. The intelligent acousto-optic call can warn the operator directly on faults which lessens the checking time and decreases the complexity of maintenance and operation.

| Technical Data | |

| Diameter | Φ100-φ1000mm |

| Length | 50-1000mm |

| Overlap | 6mm |

| Thickness | 0.4-1.2mm(27-18Ga) |

| Welding Speed | 2m/min |

| Copper Diameter | Φ2.0 |

| Power | 40kW |

| Weight | 850Kg |

| Dimension | 2300×800×1300mm |

| Voltage | 380V/50HZ/3PH |