The purpose and operating principle of an Dumaloq havo quvurlarini qayta ishlash uskunalari? This is very nice and useful of tool that workers are in use of construction to ensure that their pipes are firmly attached with each other. Ability to fit securely is very crucial for both safety and efficiency. What are the main functions it performs?

A kind of tool is that the air pipe clamp machine are used in factories and construction sites. It is used to tightly and securely connect pipes so that they do not separate. It is useful from large construction projects such as installing a big number of pipes. Workers can make sure that everything is in place by using this machine.

So here are some good reasons to use an air pipe clamp machine. Most importantly, it helps save a significant amount of time. The machine can tighten pipes together very fast, which allows workers to advance onto other jobs and tasks much quicker. Such a thing is a great help in large projects that have strict deadlines to adhere to. The Right Tools Can Have a Huge Impact When Time is Short

One more thing that makes the air pipe clamp machine worthy is that it keeps everyone safe. Loose pipes could separate when not snugly bolted together. This can cause accidents that can injure workers or harm the construction site. This makes sure that pipes are securely fastened, thus reducing accidents on job sites, and ultimately keeping everyone safer.

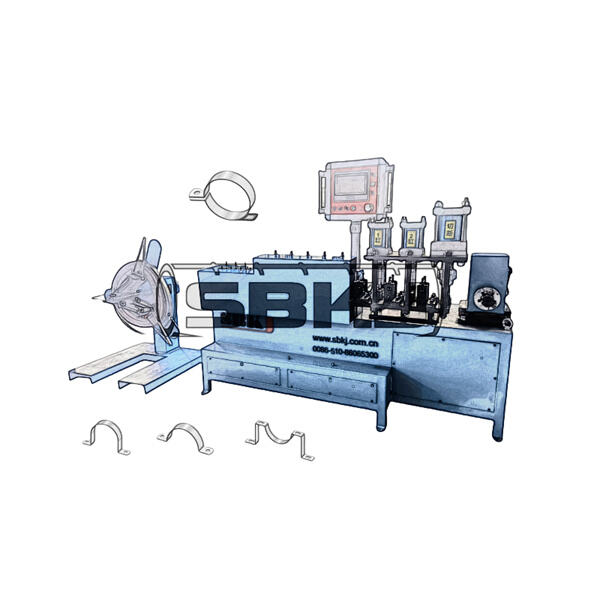

So, how does the air pipe clamp machine work actually? It is a pneumatic device that is driven by compressed air. As a worker rolls the machine up against the pipes, a tight seal is formed around them. It then squeezes and holds the pipes together. This ensures a tight, strong, and secure fit that minimizes leaks and other issues that may affect the day down the line.

Since it is designed such that it can be easily used without much formal training, workers can learn using it faster. That way they can spend less time learning how to use the tool and more time getting the job done. All of this makes it one of the most commonly used machines in construction.

If you're still using traditional methods to tie pipes together, you may need to consider switching to an air pipe clamp machine. This will save you time, increase safety, and make sure that your pipes are snug. And once you have figured it out, it is simple to use! It is amazing how changing your tools can make a significant impact on project quality.

SBKJ Group is based in the Yangtze River Delta, near Shanghai, China. SBKJ has over 30 years of experience producing spiral tubeformers from 1995. SBKJ has gotten the certificates of air pipe clamp machine and CE. SBKJ spiral tubeformer can meet the standards of DIN, BS, Euroorm and Smacna. Our customers are from over 60 countries around the world.

Every client is assigned a service representative and a dedicated after-sales hotline, as well as a dedicated after-sales WeChat group. On the Internet, you can connect with us quickly. Using the convenience of air pipe clamp machine and mobile devices, we are able to assist you quickly and assist you in solving problems. SBKJ's equipment is covered by 1 year warranty and lifelong paid maintenance.

SBKJ air pipe clamp machine OEM services. You can remove the SBKJ Logo from the device, or you can request a custom-designed device color. You can select the language of the program that you've translated into minor languages. You can also customise the software to meet your needs.

air pipe clamp machine is known as the formost and leading manufacturer of spiral ducts with several patented inventions, like the Flying silitter and the Flying crinnper. SBKJ's research and design forms the basis of our automatic tubeformers, which produce high-quality ducts at reduced costs.