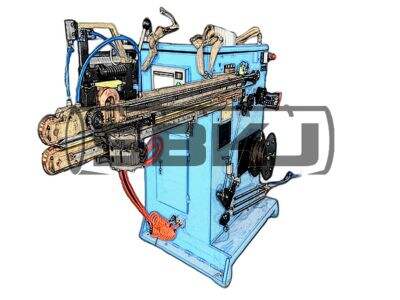

Đây là một công việc rất quan trọng và đòi hỏi nhiều kỹ năng mà nhiều người làm trong lĩnh vực này. Thợ hàn nung nóng các mảnh kim loại để kết hợp chúng một cách mạnh mẽ và an toàn. Trước đây, hàn được thực hiện thủ công và đòi hỏi nhiều thời gian và năng lượng. Nhưng giờ đây, nhờ công nghệ, chúng ta có máy móc, được gọi là "máy hàn khâu tự động", thực hiện công việc khâu. "Chúng có thể tự hàn mà không cần nhiều sự trợ giúp của con người. Trong bài viết này, chúng tôi thảo luận về lý do tại sao những chiếc máy này được coi là tương lai của ngành hàn, cũng như một số thay đổi mà chúng ta có thể nhận thấy trong công việc của mình vì chúng.

Máy hàn khâu tự động theo cách của sự kiện bạn băng tốt hơn

Chỉ là mối quan tâm với máy hàn khâu tự động Máy hàn khâu tự động là những máy móc chắc chắn sử dụng khá hiệu quả. Con người không thể thực hiện các nhiệm vụ nhanh như vậy. Vì vậy, ví dụ, trong khi một cá nhân có thể mất một khoảng thời gian đáng kể để ghép chỉ một vài mảnh, thì sẽ mất những Máy hàn tự động một phần nhỏ thời gian để hoàn thành cùng một việc. Hơn nữa, những máy này có thể hoạt động nhiều giờ mà không cảm thấy mệt mỏi. Điều đó cho phép chúng tạo ra nhiều sản phẩm hơn trong thời gian ngắn hơn, điều này rất tốt cho doanh nghiệp.

Ví dụ, công ty SBKJ SPIRAL TUBEFORMER của chúng tôi sản xuất ống gió xoắn bằng máy hàn khâu tự động. Ống gió xoắn là ống hình trụ lớn giúp truyền không khí khắp tòa nhà. [Cách chế tạo ống gió xoắn truyền thống] đòi hỏi nhiều thời gian và công sức của nhiều công nhân để chế tạo ống gió như vậy. Nhưng giờ đây chúng tôi có thể sản xuất chúng dễ dàng và nhanh chóng, nhờ máy hàn khâu tự động, cho phép chúng tôi đáp ứng nhu cầu.

Hàn rắn liên tục

Lợi ích lớn nhất của máy hàn khâu tự động là chúng có khả năng tạo ra mối hàn chắc chắn. Những máy này có thể thực hiện chính xác cùng một mối hàn mỗi lần, liên tiếp. Khả năng làm cùng một việc nhiều lần được gọi là "khả năng lặp lại. Tầm quan trọng của nó là rất lớn". Ví dụ, nếu mọi mối hàn đều giống nhau và chắc chắn, chúng ta biết rằng sản phẩm cuối cùng an toàn và đáng tin cậy.

Vâng, đôi khi con người mắc lỗi khi hàn. Bây giờ nếu một thợ hàn tạo ra mối hàn không căng tốt một mình, hoặc nếu nó trông khác với mối hàn của thợ hàn khác, Vấn đề này được gọi là "không nhất quán". MÁY LÀM HÀN KHÂU giảm thiểu những loại lỗi này, mang lại chất lượng công việc tốt hơn và sản phẩm tốt hơn”, ông nói thêm.

Bảo vệ con người trong khi hàn

An toàn là điều quan trọng vì hàn có thể là một công việc rất nguy hiểm. Trong quá trình hàn, nhiệt và ánh sáng mạnh được tạo ra rất cao, có thể gây hại cho mắt và da của con người. Hơn nữa, các chất độc thải ra khi hàn cũng rất nguy hiểm, do đó, việc thực hiện các biện pháp an toàn là bắt buộc.

Một trong những lợi thế chính của máy hàn khâu tự động là khả năng hoạt động mà không cần nhân sự ở gần. Điều này cho phép công nhân được an toàn và tránh được rủi ro khi hàn, với các máy móc hoàn thành nhiệm vụ. Hơn nữa, máy hàn khâu tự động có thể được cấu hình để hoạt động ở những khu vực quá nguy hiểm hoặc khó tiếp cận đối với con người, đảm bảo rằng cơ thể thực sự có rất ít hoặc không có rủi ro.

Lợi ích của máy hàn tự động giúp tiết kiệm chi phí

Máy hàn khâu tự động cũng giúp các công ty tiết kiệm được rất nhiều tiền. Vì những máy này có thể thực hiện các nhiệm vụ hàn mà không cần nhiều nhân sự, nên các công ty không phải trả tiền cho nhiều người để làm công việc này. Điều này giúp giảm chi phí lao động liên quan đến việc bảo dưỡng hàng tồn kho. Hơn nữa, các doanh nghiệp có thể sản xuất nhiều sản phẩm hơn trong thời gian ngắn hơn vì máy có thể hoạt động nhiều giờ mà không cần nghỉ.

Ví dụ, với chúng tôi, SBKJ SPIRAL TUBEFORMER, chúng tôi cần rất nhiều nhân công để sản xuất ống xoắn ốc. Vì có máy hàn khâu tự động nên chỉ cần một số ít người vận hành những máy này. Điều này giúp chúng tôi tiết kiệm được rất nhiều tiền và cho phép chúng tôi tập trung vào những thứ lớn hơn và tốt hơn.

Máy hàn khâu tự động: Tương lai của ngành hàn

Bạn đã nghe về máy hàn khâu tự động chưa? Chúng góp phần làm cho việc hàn nhanh hơn, an toàn hơn và dễ dàng hơn. Những thiết bị này cũng cho phép hàn những vật thể mà trước đây quá khó để hàn, do đó cho phép các phương pháp sản xuất thực hiện các khả năng hoàn toàn mới.

Theo thời gian, chúng ta có thể mong đợi thấy máy hàn khâu tự động được sử dụng ngày càng nhiều hơn trong các ngành công nghiệp trên toàn thế giới. Những chiếc máy này sẽ ngày càng tốt hơn, tinh vi hơn và có thể đảm nhiệm các nhiệm vụ phức tạp. Hơn nữa, với những tiến bộ trong công nghệ, máy hàn khâu tự động dự kiến sẽ trở nên rẻ hơn, cho phép ngay cả các doanh nghiệp nhỏ hơn cũng có thể mua được.

Phần kết luận

Tóm lại, tự động MÁY HÀN ĐƯỜNG MAY thực sự là tương lai của ngành hàn. Nó làm cho quá trình hàn nhanh hơn và an toàn hơn, đồng thời cũng tiết kiệm tiền cho doanh nghiệp. Những chiếc máy này có thể là một bước ngoặt trong thế giới hàn. Đảm bảo rằng ống dẫn xoắn ốc của chúng tôi có chất lượng cao nhất, SBKJ SPIRAL TUBEFORMER tự hào sản xuất ống dẫn của họ bằng những công cụ máy móc đáng chú ý này. Tóm lại, chúng tôi nghĩ rằng máy hàn khâu tự động là một yếu tố thiết yếu của tương lai ngành hàn và chúng sẽ tiếp tục như vậy trong những năm tới.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

HY

HY

BN

BN

LO

LO

LA

LA

MN

MN

NE

NE

UZ

UZ

KY

KY