have you seen a folded tube or corrugated tube? A corrugated tube is a type of tube that is deposited with small, parallel ridges running vertically on its surface. These ridges add strength and durability to the tube. Different types of materials can be used to manufacture the corrugated tubes; however, aluminum corrugated tube is a well-known choice. That is mainly because aluminum Corrugated Spiral pipe has the advantage of being easy to transport due to its low weight, and remaining in good conditions for a long time, even when exposed to harsh environmental conditions (it does not rust). Creating aluminum corrugated tubes could be challenging, as they need to be prepared with great precision and uniformity. This is where a company SBKJ Spiral Tubeformer comes into help!

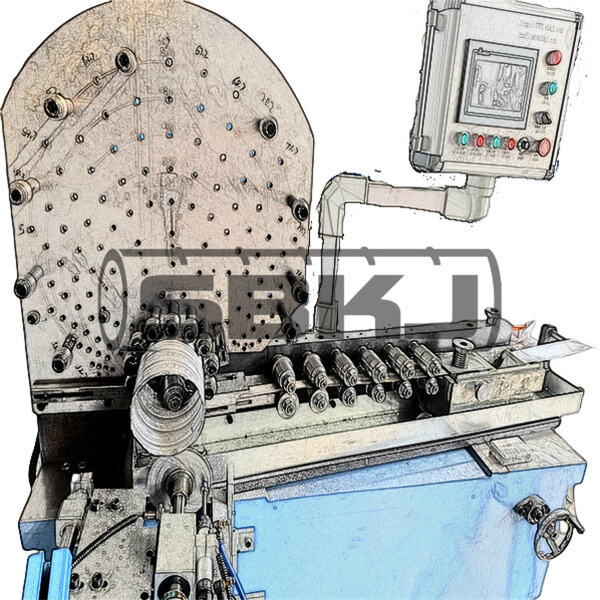

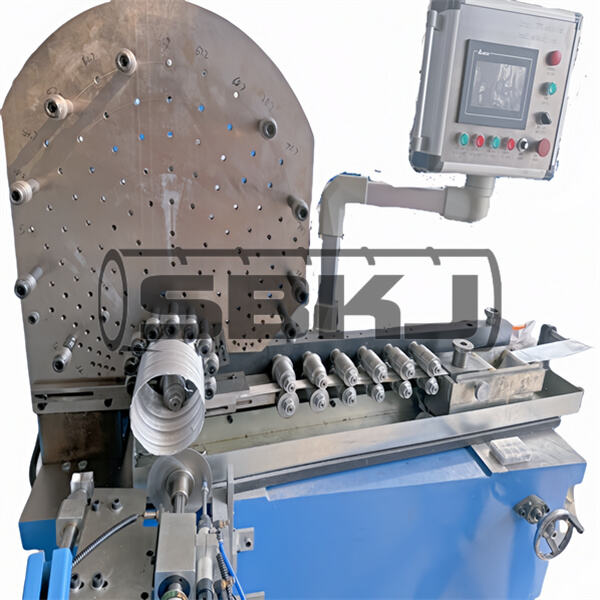

SBKJ Spiral Tubeformer is an excellent manufacturer to manufacture big rolls of aluminum in a corrugated way. They are highly skilled in this as they use unique technology which helps them ensure that the tubes come out impeccable with the perfect shapes. It begins with a giant aluminum roll put through a Automatic Welding Machine specifically designed for this. The Roll is first cut to the narrow width, which is how wide the tube will be. It then moves on to a set of rollers that form the corrugated shape into the aluminum. The result is an extremely rigid aluminum corrugated tube that withstands extreme environments—hot, cold, or wet.

Careful engineering is one of the critical steps in producing high-quality aluminum corrugated tubes. SBKJ Spiral Tubeformer has devoted huge amounts of time and expenditure to taking advantage of up-to-date technology, ensuring each and every tube is uniform in design and measurements. As the Automatic Stitchwelder machines they utilize are programmed extremely precise with measurements & settings during the formation process. This means that each tube is formed to a very tight tolerance. This precision creates homogeneous tubes, as in they are the same visually and possess the same characteristics. It matters here, because manufacturers need dependability in tubes for their own products.

However, the applications that can use aluminum Round Flange Forming corrugated tubes are another benefit they offer. Meaning they may be used for a vast array of purposes. This makes them commonly used in heating and cooling systems, and also the automotive industry for cars and trucks. They can also customize the design of these tubes according to the special needs as per the customer requirements. They can make tubes of various diameters (how wide) and wall thicknesses (how thick the sides are). This customisation is extremely helpful as various projects may call for non-standard tubes. The tubes can also be coated or painted to increase their resistance to corrosion and exposure to other environmental elements.

With increasing demand of aluminum corrugated tubes, manufacturers must adopt with advance production methods. Here, automatic tube forming machines are a must. We, SBKJ Spiral Tubeformer with the full state-of-the-art machines capable of generating industries when needed, it produces very fast and efficient tubes. The machines are designed at doing the majority of work and hence lessen labor costs and results in more productivity for the factory. Since the machines can be run entirely on automation, operating them are much simpler and that allows workers to focus more time and attention on other important. They also give them the ability to scale up – Which makes them a perfect option for small to medium-scale manufacturing companies looking to expand.

ALUMINUM CORRUGATED TUBEFORMER provides OEM services. You can opt to eliminate the SBKJ logo from your device or request a customised color for the device. The language that the software uses can be set in the event that you provide translations for languages that are not major. We can also customize the equipment you need according to your production requirements

SBKJ Group is based in the Yangtze River Delta, near Shanghai, China. SBKJ has over 30 years of experience producing spiral tubeformers from 1995. SBKJ has gotten the certificates of ALUMINUM CORRUGATED TUBEFORMER and CE. SBKJ spiral tubeformer can meet the standards of DIN, BS, Euroorm and Smacna. Our customers are from over 60 countries around the world.

We offer a dedicated customer service representative for every client along with an after-sales hotline that is fixed and a WeChat Group that is devoted to after-sales. Online, you can find us easily. Relying on the convenient Internet, we can also promptly assist you and assist you with problems. SBKJ's equipment comes with an one-year ALUMINUM CORRUGATED TUBEFORMER and lifetime paid maintenance.

SBKJ is established as the ALUMINUM CORRUGATED TUBEFORMER in spiral duct manufacturing using patented inventions such as the Flying silitter and the Flying crinnper. SBKJ's research and development is the basis of our automatic tubeformers that produce high quality ducts at lower costs.