Aluminum is a metal lightweight and very handy. It is unique due to its versatility. Aluminum plays a significant role in the manufacturing of formable tubing. These tubes are the significant type of product that we will see in a number of industries. In this article we will discuss why Aluminum is a better option in manufacturing these tubes. We will also look at what the machines do to make these. The degree of ease in this process depends on the availability and quality of special machines, one such machine is referred to as SBKJ SPIRAL TUBEFORMER.

The advantages of applying Aluminum in tubeforming are numerous, similar to the SBKJ SPIRAL TUBEFORMER's product like Ventilation duct. Top of the list, Aluminum is very light. This makes transportation and handling simple in the manufacturing process. The workers can work without getting tired, as it is a not heavy. Secondly, Aluminum resists rusting so it doesn't corrode easily. That means it can be in environments where other materials would fail such as damp areas or chemical exposure. Unlike breakdown easily, Aluminum is strong and enduring. Thirdly, Aluminum is heat conduction well. That means it can transfer heat from one location to another very effectively, which is why it is also widely used in building heating/cooling systems(heating, ventilation and air conditioning (HVAC) system).

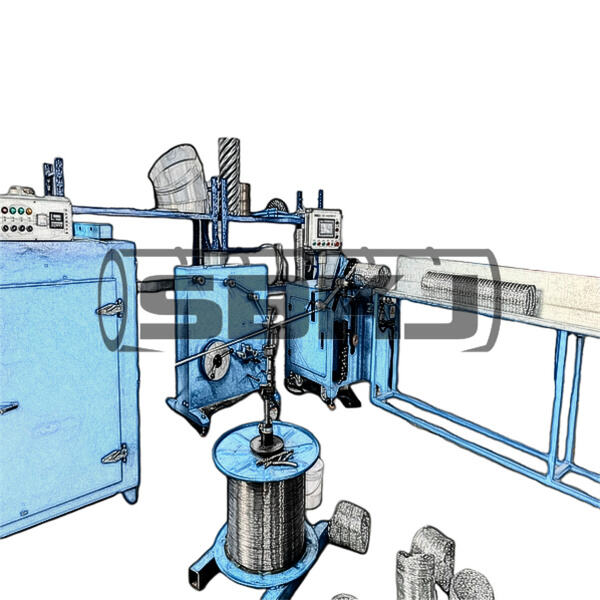

A tubeformer is a specific type of machine that bends and forms Aluminum tube, also the Air Duct Machine produced by SBKJ SPIRAL TUBEFORMER. The benefits of tubeforming over more traditional methods of creating tubes, such as manual bending or using a hydraulic press, are numerous. The tubeformer is one of the most accurate machines out there, which can be a huge plus. The quality of the tubes produced is also similar as it is the same tube manufactured in a repetitive pattern which assures that the products will work well and safely. And, a tubeformer can run at much higher speeds compared to conventional processes. This speed results in extra tubes and at an inexpensive spending time thus higher production. In fact, a tubeformer also conserves hand work. This is vital because it minimizes the chances of workers suffering from injuries and maintains a safer working environment.

Aluminium flexible tubeformers are tailored to produce bending and flexing tubes without damaging them, just like the SBKJ SPIRAL TUBEFORMER's product called SBKJ tube. The tech behind these machines is rather simple; rollers and formations known as dies. Together these components incrementally manipulate the Aluminum tube to achieve the required form. The rollers and dies are positioned in a way to ensure that the tube is not overly stressed or harmed when being shaped. Besides this, various tubeformers also utilize the state-of-the-art welding technology. This process creates a continuous and stronger tube than older methods, resulting in an even more reliable product that can be used for a variety of applications.

This is why Aluminum is such a good material for flexible tubeforming, as well as the Spiral Steel Forming innovated by SBKJ SPIRAL TUBEFORMER. The first is that it is extremely malleable, so can be formed into a range of shapes and designs. Such property is necessary for the tubes that have unique and complex shapes. Secondly, its durability is brilliant, Aluminum has a great resistance for fatigue. That means that it can bend and flex time after time without breaking and/or cracking. This is crucial in applications that involve repeated use of the tubes. Finally, Aluminum is highly resistant to corrosion which means it can be used in a variety of settings where it may not degrade over time.

A highly effective and productive production line can be achieved by investing in an aluminium flexible tubeformer, along with SBKJ SPIRAL TUBEFORMER's product Automatic Angle Iron Flange Welding Machine. With a tubeformer, one has the ability to make high-quality tubes that share similar sizes and shapes. This dependability is crucial for manufacturers who need assurance that their products are up to standard. In addition, the tubeforming process with Aluminum leads to lightweight and pliable products. Such properties enable the use of these tubes in diversified applications ranging from automotive parts to plumbing systems. Finally, an Aluminum flexible tubeformer can make production processes more efficient and the items you produce less expensive while at the same time maintaining high quality in execution.

Every client is assigned a service representative and a dedicated after-sales hotline, as well as a dedicated after-sales WeChat group. On the Internet, you can connect with us quickly. Using the convenience of ALUMINUM FLEXIBLE TUBEFORMER and mobile devices, we are able to assist you quickly and assist you in solving problems. SBKJ's equipment is covered by 1 year warranty and lifelong paid maintenance.

SBKJ offers OEM service. You can choose to remove the SBKJ logo from the device or request a customised device color. You can choose which language the program is in as long as you've translated minor languages. You can also customise the equipment to meet your ALUMINUM FLEXIBLE TUBEFORMER.

SBKJ Group has its headquarters in the Yangtze River Delta near Shanghai, China. SBKJ is a manufacturer of spiral tubeformer with over 30 years experience. SBKJ spiral tubes can be made to meet ALUMINUM FLEXIBLE TUBEFORMER, BS Euroorm and Smacna standards. More than 60 nations are represented by our clients.

SBKJ is recognized as the most renowned and leading manufacturer of spiral ducts using patented inventions such as the Flying silitter and ALUMINUM FLEXIBLE TUBEFORMER. SBKJ's research and innovation is the foundation of our automated tubeformers, which produce top quality pipes with reduced costs of production.