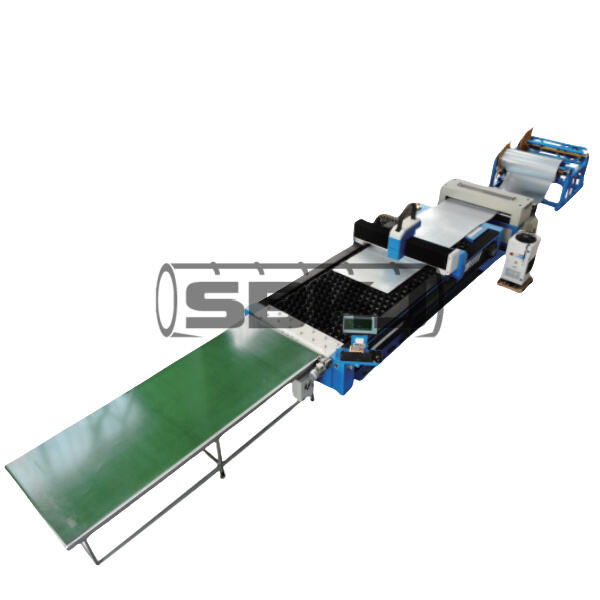

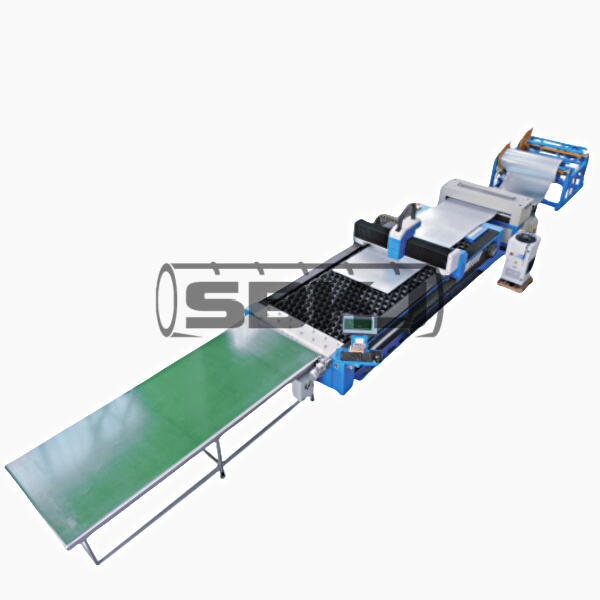

A laser welder is a unique type of machine that joins different materials with a super-intense beam of light. HJZ is a laser welder by SBKJ SPIRAL TUBEFORMER. That is because they are highly cost-effective, because they are accurate, and because they can work accurately in an automated fashion. They can weld across a range of different materials, including metal and plastic. Keep reading for a closer look at how the HJZ laser welder works, and more details on its importance!

If we talk about how accurate are HJZ laser welder, then answer is, it is a very accurate machine. It can weld tiny sections with extreme care and accuracy. This is really important for factories, because it enables them to manufacture products with high fit-to-function. For instance, if a factory needs to assemble a miniature medical device, the HJZ laser welder can join the componentry by carefully welding them together. This accuracy is crucial to making sure the medical device is safe to implant and functions properly for patients.

A main benefit of HJZ is, it has high efficiency. This means that it can fast weld materials that save time and energy. It also produces less waste than traditional welding processes. This because the laser beam is focused and can heat up to the materials very fast. Because it heats up so quickly, the materials are less likely to be damaged by the weld. In general, this on its own renders the HJZ laser welder a wise decision for a lot of startups.

For instance, in the aerospace industry, the HJZ laser welder is employed to meld components that are required for aircraft. They also have to be extremely accurate, as well as robust, to ensure passenger grounded and security flying. A slight mistake when welding can cause severe problems, making the HJZ laser welder ideal for this task. It supplies the precision and strength that is necessary in airplane manufacturing.

In electronics, the HJZ laser welder is used to weld small parts. This is particularly critical as electronic devices, such as smartphones and computers, are required to be small and extremely accurate. To build such devices precisely and strictly to size, manufacturers can turn to the HJZ laser welder to help them achieve a working unit. It would be much harder to make small electronic devices without this technology.

Having an extremely powerful weld is one of the advantages of using the HJZ laser welder. For high-stress applications the welds must be strong. For instance, components of a vehicle can be welded together using the HJZ laser welder in automotive manufacturing. These welds need to be extremely strong to protect the driver and passengers. Bad welds could result in dangerous conditions while driving.

Ultimately, HJZ laser welder is the equipment for many different industries. It is then, efficient, and versatile, making it a great welding choice. It is helpful for welding multiple types of materials and producing durable dependable welds. This makes it the most sophisticated welding device currently available in the market to produce parts as per exact specifications or standards demanded by manufacturers.

SBKJ Group has its headquarters in the Yangtze River Delta near Shanghai, China. SBKJ is a manufacturer of spiral tubeformer with over 30 years experience. SBKJ spiral tubes can be made to meet hjz laser welder, BS Euroorm and Smacna standards. More than 60 nations are represented by our clients.

hjz laser welder provides OEM services. You can opt to eliminate the SBKJ logo from your device or request a customised color for the device. The language that the software uses can be set in the event that you provide translations for languages that are not major. We can also customize the equipment you need according to your production requirements

We provide a dedicated customer service representative for every client along with a fixed After-Sales Service Hotline and an after-sales hjz laser welder dedicated to the after-sales. You can find us on the internet. We can quickly solve your problems using the Internet. SBKJ equipment is covered by a lifetime service program and a guarantee of one year.

SBKJ has been a pioneer in the production of spiral ducts industry for several years. They have a number of patents like Flying silitter Flying crinnper, and Flying teeter. SBKJ's research and development is the hjz laser welder of our automated tubeformers that create high-quality tubes with lower production costs.